Lithium battery packs, as the cornerstone of energy storage systems, are typically composed of multiple batteries connected in series or parallel. However, discrepancies in manufacturing, aging rates, and temperature variations can lead to inconsistencies in voltage and capacity among single cells. These imbalances can significantly affect the overall performance, lifespan, and safety of the battery pack.

Moreover, during idle periods, the chemical reactions within lithium batteries cause a gradual loss of charge. This self-discharge characteristic further exacerbates imbalances between batteries, posing additional challenges to the battery system.

Capacity Limitation: The overall capacity of a battery pack is determined by the cell with the lowest capacity, limiting the output capability in general. Overuse of these lower-capacity cells may accelerate capacity degradation.

Charging and Discharging Imbalance: Voltage differences during charge and discharge cycles can lead to overcharging or over-discharging of some batteries, increasing the risk of thermal runaway and shortening battery lifespan.

Reduced Energy Efficiency: Variations in battery performance decrease the energy utilization efficiency of the storage system, leading to higher operational costs.

Addressing these challenges requires advanced battery balancing strategies and robust management systems to optimize the performance and safety of lithium battery packs. These strategies are categorized into two primary types: passive balancing and active balancing.

Passive Balancing

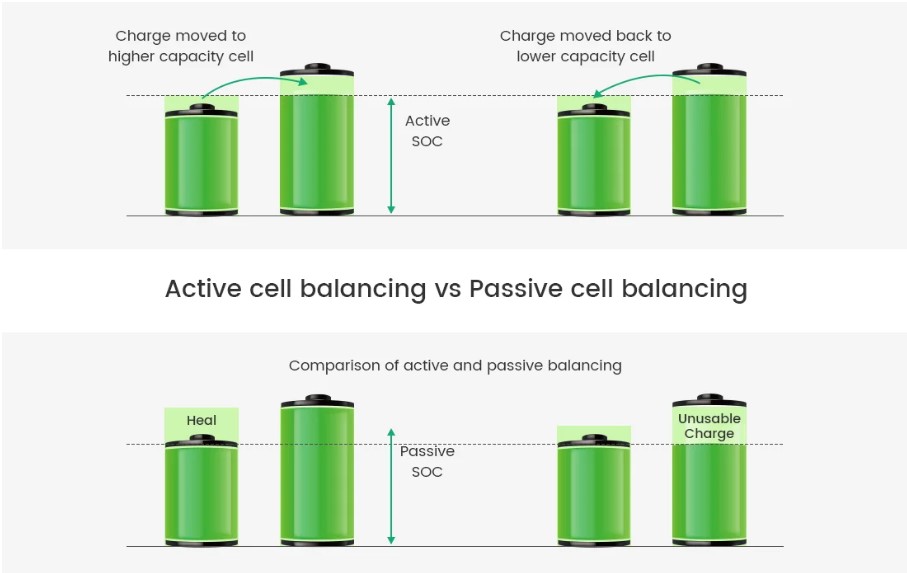

Passive balancing involves discharging the excess energy from higher-voltage cells through resistors, converting the surplus energy into heat to bring cell voltages into balance. This is the most common balancing method due to its low cost and straightforward implementation. However, the effectiveness of passive balancing is often constrained by the capacity of the lowest-performing battery in the pack, leading low energy utilization efficiency and significant heat loss.

Active Balancing

Active balancing redistributes energy from higher-energy cells to lower-energy ones through charge transfer. This approach typically relies on inductors, transformers, or capacitors as energy storage components, significantly improving energy efficiency. Active balancing is well-suited for large-capacity, high-series battery systems. However, its complexity in circuit design, higher hardware requirements, and associated costs make it more suitable for high-performance applications.

Comparison of Passive and Active Balancing

The Battery Management System (BMS) is the core control unit of a lithium battery pack, tasked with real-time monitoring and management of each cell's operational status to ensure performance and safety. The BMS plays a critical role in battery balancing by offering the following advantages:

Energy Optimization: Advanced algorithms enable the BMS to maximize balancing efficiency and minimize energy loss.

Battery Longevity: By ensuring each cell operates within a safe range, the BMS prevents overcharging and over-discharging, extending the battery pack's overall lifespan.

Safety Assurance: The BMS provides real-time safety monitoring during the balancing process, preventing potential risks such as thermal runaway caused by poor balancing.

The Gerchamp G-BS for ESS ensures stable operation of lithium battery packs by continuously monitoring key parameters such as battery voltage, temperature, and current. Its advanced balancing capabilities maximize efficiency, with the G-BMU module supporting intelligent cell-level balancing control, which, avoids interference with cell voltage and temperature data acquisition.